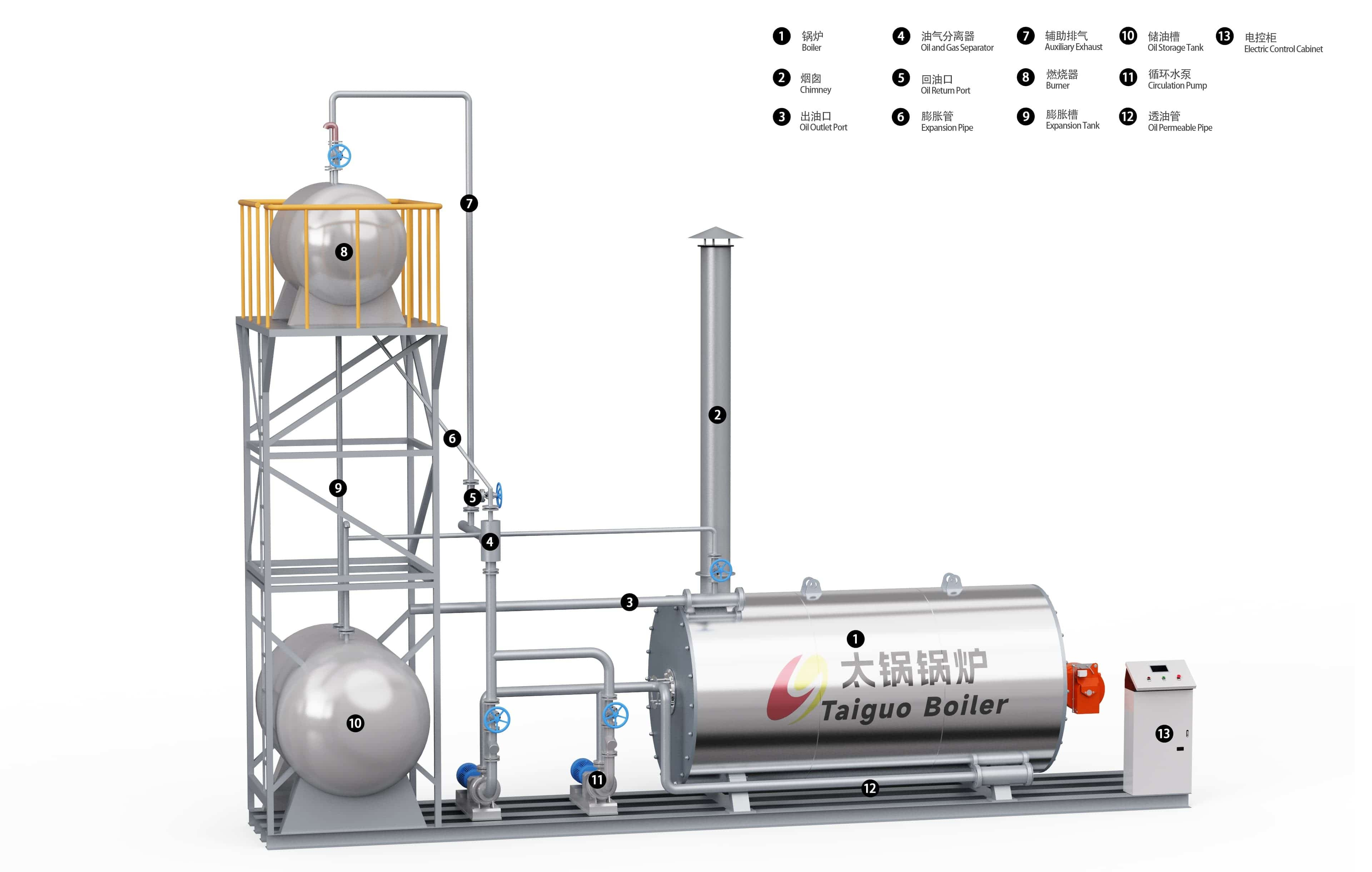

YYQW series gas/oil thermal oil boiler adopts a three-pass circular coil design, with a rear conical coil protecting the furnace wall. Heat is transferred by radiation in the first pass, then through convection coils in the second and third passes before exiting via the economizer and chimney. Delivered as a complete unit, it requires only gas (oil) and power connections for operation.

Advantages

1. High Thermal Efficiency

Three-pass coil structure ensures excellent heat transfer and stable thermal efficiency.

2. Safe & Reliable Operation

Conical coil design protects the furnace wall, while advanced safety systems ensure secure operation.

3. Fully Automatic Control

Equipped with an intelligent burner and control system for easy, unattended operation.

4. Energy-Saving Design

Optimized combustion and heat recovery reduce fuel consumption and operating costs.

| Model ltem |

YY(Q)W 350 |

YY(Q)W 500 |

YY(Q)W 700 |

YY(Q)W 1400 |

YY(Q)W 2100 |

YY(Q)W 2800 |

YY(Q)W 3500 |

YY(Q)W 4200 |

YY(Q)W 7000 |

YY(Q)W 14000 |

||

| Rated thermal p ower |

KW | 350 | 500 | 700 | 1400 | 2100 | 2800 | 3500 | 4200 | 7000 | 14000 | |

| Design pressure | Mpa | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |

| Medium outlet temperature | C | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | |

| Heating area | m | 21.3 | 24 | 40 | 78.5 | 94.5 | 157 | 205.2 | 240 | 410 | 710 | |

| Fuel | light oil/heavy/LNG/CG | |||||||||||

|

Fuel |

Light oil | Kg/h | 37 | 52 | 69 | 140 | 210 | 280 | 350 | 420 | 680 | 1360 |

| LNG | Nm3/h | 44 | 63 | 83 | 170 | 260 | 332 | 425 | 498 | 810 | 1620 | |

| Thermal efficiency | 96% | 96% | 96% | 96% | 96% | 96% | 96% | 96% | 96% | 96% | ||

| Furnace oil content | m3 | 0.25 | 0.3 | 0.5 | 1.1 | 1.7 | 2.29 | 3.8 | 4.3 | 7 | 15.5 | |

| Boiler dimensions | mm |

2100× 1390× 2055 |

2200× 1390× 2055 |

3240× 1470× 2260 |

4145× 1900× 2786 |

5020× 2050× 3080 |

5526× 2326× 3230 |

6555× 2470× 3634 |

6753× 2838× 3704 |

8200× 3050× 3800 |

12000× 3780× 4350 |

|

| Boiler transport weight | T | 2.58 | 3 | 3.7 | 6.9 | 8.8 | 11.5 | 17.8 | 19.8 | 27.5 | 42 | |

| Oil inlet | DN | 80 | 100 | 100 | 125 | 150 | 150 | 200 | 200 | 250 | 350 | |

| Oil outlet | DN | 80 | 100 | 100 | 125 | 150 | 150 | 200 | 200 | 250 | 350 | |

| Expansion tank | m3 | 1.5 | 1.5 | 1.5 | 2.5 | 2.5 | 3 | 3 | 4.5 | 6 | 8 | |

| Storage tank | m3 | 2.5 | 2.5 | 2.5 | 5 | 5 | 8 | 8 | 10 | 15 | 25 | |

| ChimneyΦ | mm | 280 | 280 | 280 | 350 | 400 | 400 | 500 | 500 | 700 | 1000 | |

Why Choose Us?

Founded in 1976, Taiguo Boiler is National Designated A-Class Boiler Manufacturer to produce Class A boilers and D1/D2 pressure vessels, offering customized solutions from design to installation and commissioning, including boiler room planning.

Project Cases

Our boilers are exported worldwide and trusted by customers in Asia, Europe, Africa, and South America. With rich export experience, we deliver efficient and customized solutions, earning a strong reputation for quality and service.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.