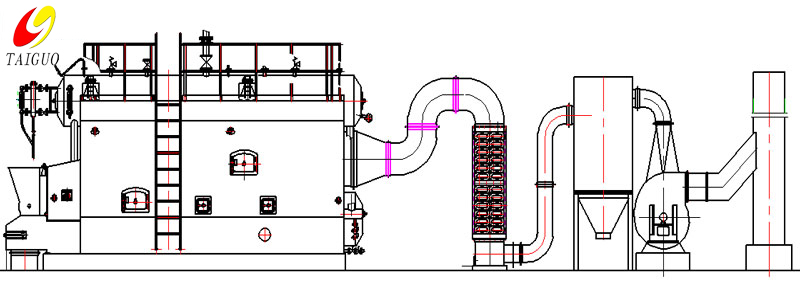

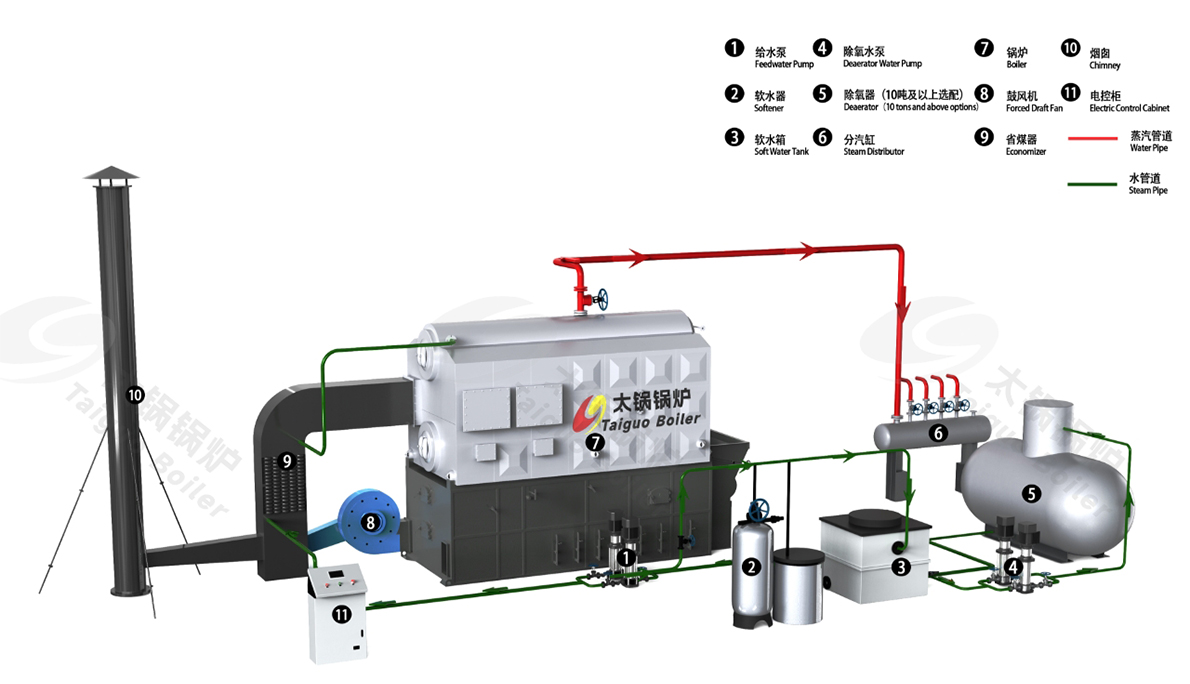

SZL biomass fired chain grate steam boiler is horizontal type water tube boiler, the combustion equipment is chain grate. The boiler adopts fast assembly or packaged assembly structure, boiler with steam capacity lower than 4t/h is fast assembly water tube structure, boiler with steam capacity between 6~25t/h is consisted of upper part (boiler heated part) and lower part (combustion equipment). The boiler is equipped with water-cooled walls, a steam-water separator, a blowdown system, and an economizer. This series of boilers has reached international advanced levels in terms of technology, performance, and environmental protection.

Applications: Foods, Garment, Textile, Paper, Brewery, Ricemill, Printing & Dyeing, Poultry feed, Sugar, Packaging, Plywood, Building material, Chemical, etc.

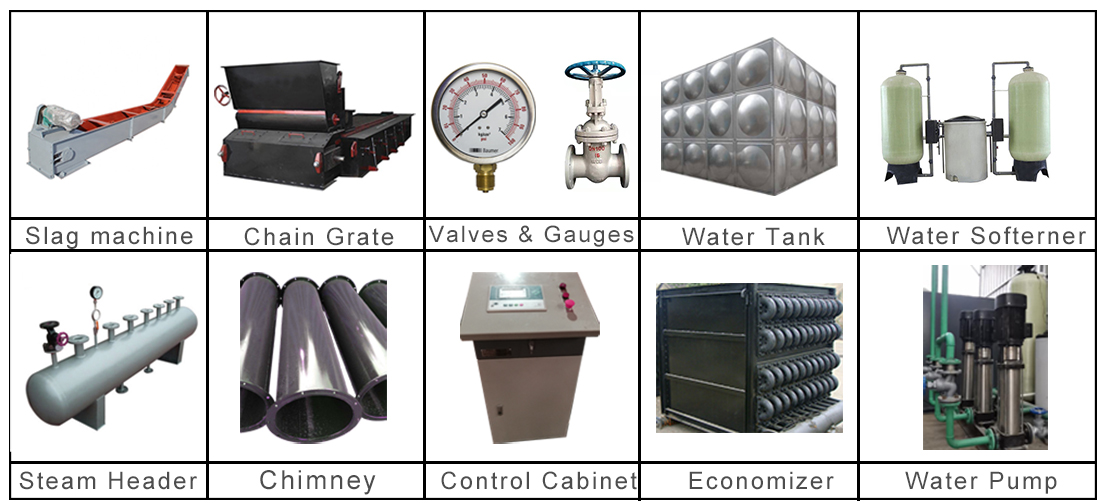

Whole SZL series biomass boiler system includes grate, boiler body, economizer, dust collector, flue, air duct, induced draft fan, blower, slag remover, loading machine, water pump, deaerator, etc.

SZL Series Biomass Fired Steam Boiler:

Model |

Rated Steam Capacity (t/h) |

Working Pressure (MPa) |

Thermal Efficiency (%) |

Overall Dimension L×W×H (m) |

Weight (t) |

SZL2-1.25/1.6/2.5 |

2 |

1.25/1.6/2.5 |

81 |

5.8×2.35×3.5 |

25 |

SZL4-1.25/1.6/2.5 |

4 |

1.25/1.6/2.5 |

81 |

7.8×2.4×3.6 |

32 |

SZL6-1.25/1.6/2.5 |

6 |

1.25/1.6/2.5 |

81 |

8×3×4.87 |

43 |

SZL8-1.25/1.6/2.5 |

8 |

1.25/1.6/2.5 |

81 |

8.1×3.2×5.7 |

63 |

SZL10-1.25/1.6/2.5 |

10 |

1.25/1.6/2.5 |

81 |

8.2×3.5×5.7 |

87 |

SZL12-1.25/1.6/2.5 |

12 |

1.25/1.6/2.5 |

81 |

10.6×3.6×5.7 |

100 |

SZL15-1.25/1.6/2.5 |

15 |

1.25/1.6/2.5 |

82 |

12.5×3.7×5.8 |

105 |

SZL20-1.25/1.6/2.5 |

20 |

1.25/1.6/2.5 |

82 |

13.8×4.2×5.8 |

140 |

SZL25-1.25/1.6/2.5 |

25 |

1.25/1.6/2.5 |

82 |

15.6×5×6.135 |

170 |

SZL30-1.25/1.6/2.5 |

30 |

1.25/1.6/2.5 |

82 |

17.7×8.5×9.5 |

210 |

Note:1.Parameter is for reference only, if any changes should follow the factory technical data. | |||||

SZL Series Biomass Fired Hot Water boiler:

Model |

Rated Power (MW) |

Working pressure (Mpa) |

Supply water temperature (℃) |

Return water temperature (℃) |

Thermal efficiency (%) |

SZL1.4-0.7/95/70 |

1.4 |

0.7 |

95 |

70 |

80 |

SZL2.8-0.7/95/70 |

2.8 |

0.7 |

95 |

70 |

80 |

SZL4.2-1.0/95/70 |

4.2 |

1 |

95 |

70 |

80 |

SZL5.6-1.0/95/70 |

5.6 |

1 |

95 |

70 |

80 |

SZL7-1.0/95/70 |

7 |

1 |

95 |

70 |

80 |

SZL10.5-1.0/115/70 |

10.5 |

1 |

115 |

70 |

80 |

SZL14-1.0/115/70 |

14 |

1 |

115 |

70 |

80 |

Note: 1.Parameter is for reference only, if any changes should follow the factory technical data. | |||||

Why Choose Us?

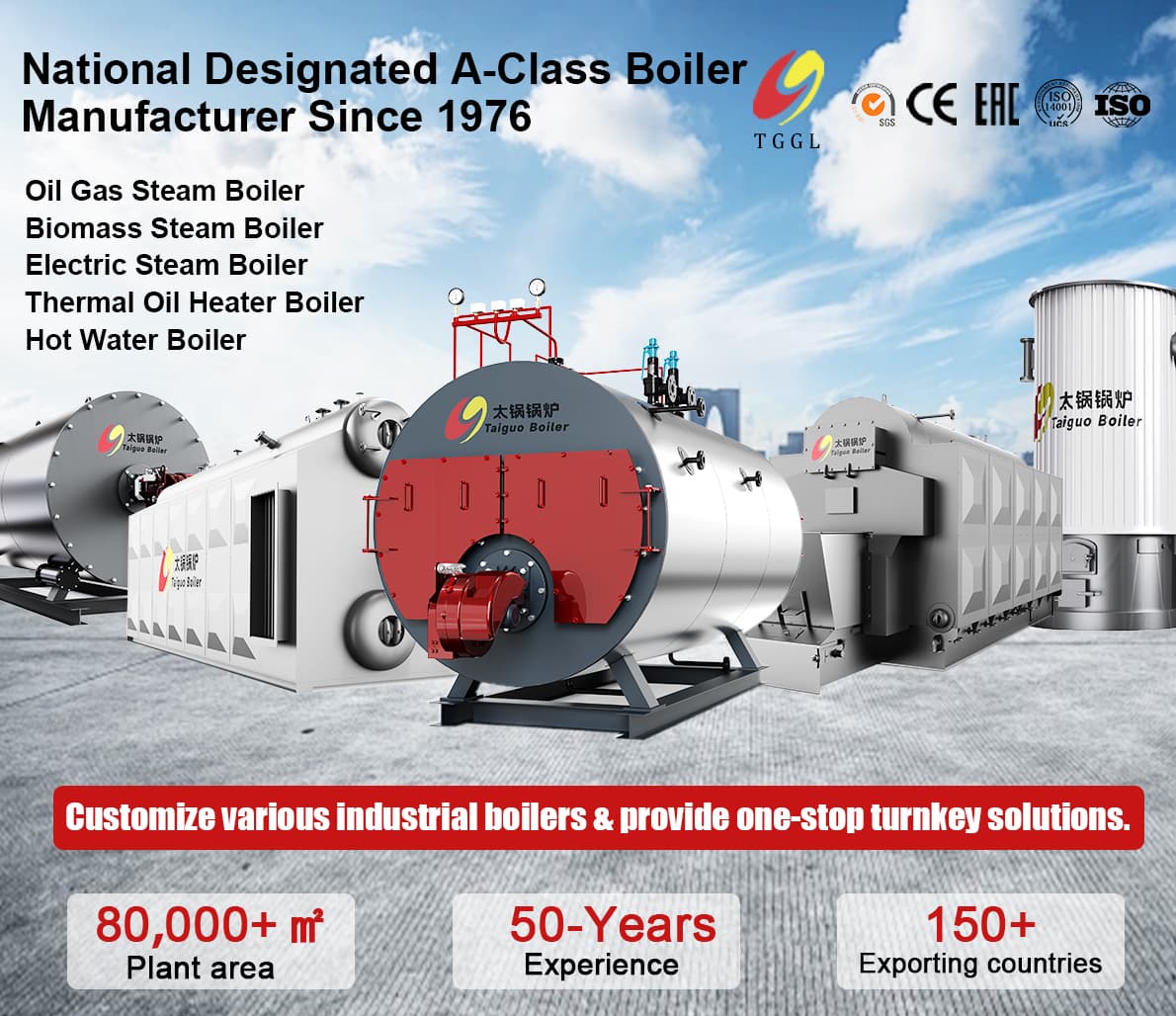

Founded in 1976, Taiguo Boiler is National Designated A-Class Boiler Manufacturer to produce Class A boilers and D1/D2 pressure vessels, offering customized solutions from design to installation and commissioning, including boiler room planning.

Project Cases

Our boilers have been successfully exported worldwide, serving customers across Asia, Europe, Africa, and South America. With extensive export experience, we provide reliable performance, high efficiency, and customized solutions to meet diverse industrial needs. Trusted by global clients, our products have earned an excellent reputation for quality and service.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.