Introduction

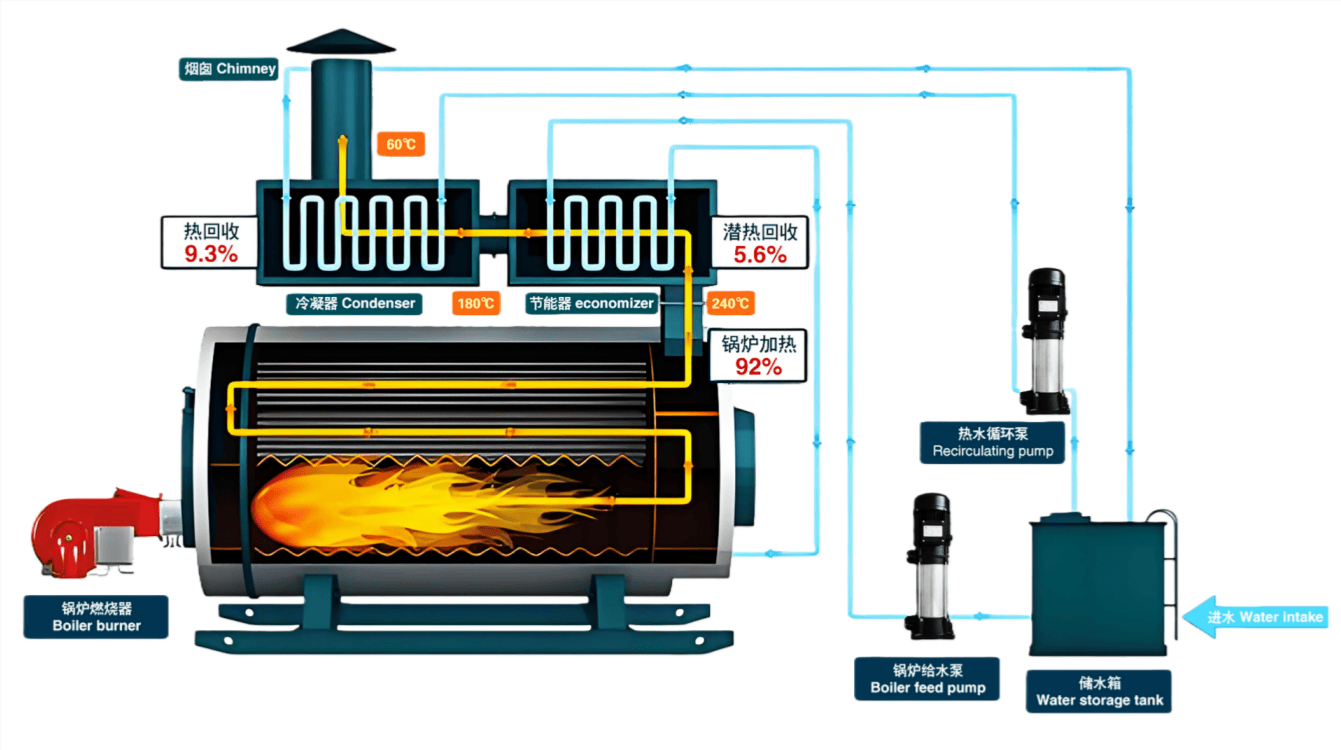

CWNS series is a horizontal three-pass, packaged fire tube hot water boiler operating under atmospheric pressure. It features a wet-back design, with flue gas passing through the second and third passes before discharge. Equipped with a world-class burner and advanced automatic control system, it offers protection against high water temperature, over-temperature, and over-pressure.

Advantages

1.Thermal efficiency≥95%, the economizer and condenser can reuse the waste heat

2.Fully automatic and safe operation, advanced control system enables unattended operation

3.Easy to operate and maintain, boiler internet of things +remote control + experts management

4.Advanced low nox burner, environmental protection, nox emission ≤30mg/Nm³

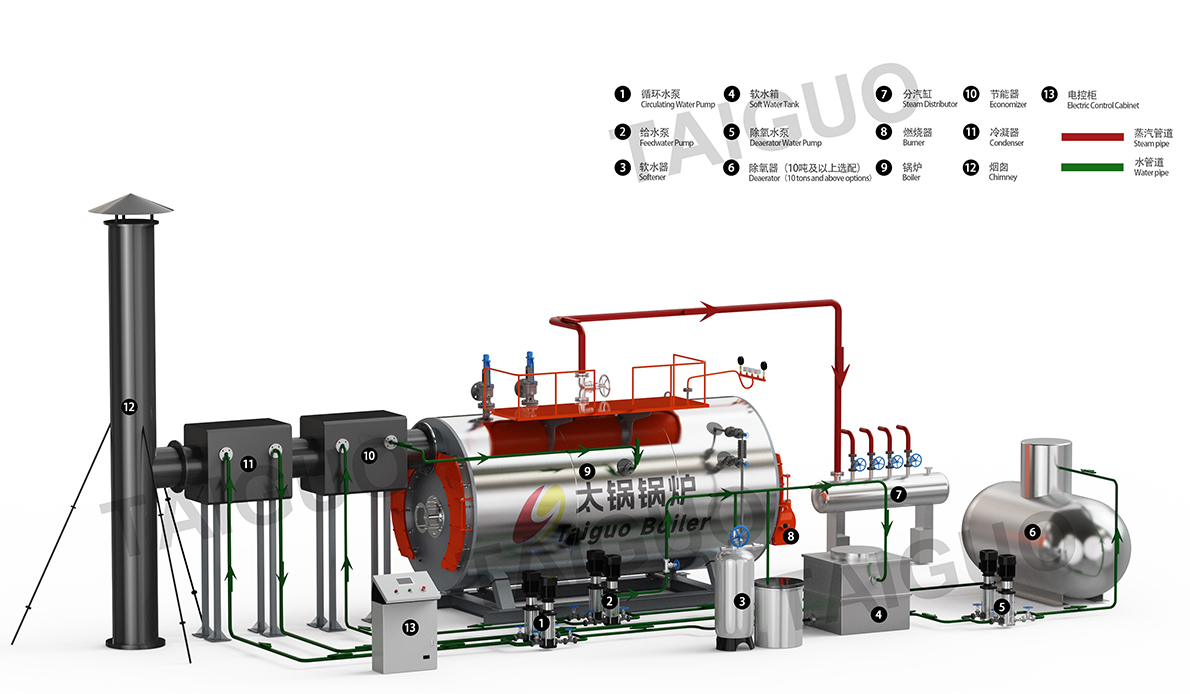

5.With its skid-mounted base, users only need to provide water, electricity, and fuel to start the boiler immediately.

WNS Low-NOx Condensing Integrated Hot Water Boiler Heating Process

Project Cases

Our boilers are exported worldwide and trusted by customers in Asia, Europe, Africa, and South America. With rich export experience, we deliver efficient and customized solutions, earning a strong reputation for quality and service.

1. Burner – Italy Baltur or other brands as specified.

2. Control Cabinet – Full automatic PLC system with English display.

3. Water Pump – Brand optional; variable frequency supply for energy savings.

4. Economizer – Optional to improve thermal efficiency.

5. Water Treatment – Options based on water quality, such as softening or reverse osmosis.

Standard configuration shown above; other accessories like condensate recovery, deaerator, and pressure tank are also available. For details, please send an inquiry.

Item |

WNS0.7 |

WNS1.4 |

WNS2.1 |

WNS2.8 |

WNS3.5 |

WNS4.2 |

WNS5.6 |

WNS7 |

WNS10.5 |

WNS14 |

|

Rated power(MW) |

0.7 |

1.4 |

2.1 |

2.8 |

3.5 |

4.2 |

5.6 |

7 |

10.5 |

14 |

|

| Rated working pressure(Mpa) | Atmospheric pressure/0.7/1.0 |

||||||||||

Rated effluent temperature(℃) |

85/95/117 |

||||||||||

| Rated return water temperature(℃) | 60/70/70 |

||||||||||

| Thermal efficiency(%) | 98 |

||||||||||

Thermal efficiency(㎡) |

35 |

53 |

77 |

107 |

127 |

198 |

212 |

272 |

358 |

448 |

|

| Energy saver heating area (㎡) | 11 |

12 |

15 |

22 |

30 |

35 |

45 |

60 |

70 |

80 |

|

| Suitable fuel | Natural gas/LPG/LNG/City gas/Biogas/ Diesel /Heavy Oil | ||||||||||

|

Fuel consum ption |

Diesel(Kg/h) | 61 | 121 | 182 | 241.5 | 302 | 362 | 485 | 612 | 905.6 | 1207.5 |

| Natural gas(Nm³/h) | 70 | 140.5 | 210.6 | 283 | 351.5 | 422.4 | 563 | 705.5 | 1055 | 1408 | |

Weight(t) |

7.1 |

8.2 |

9.9 |

12.7 |

14.2 |

17.5 |

21.3 |

22 |

35.5 |

45 |

|

| Maximum transport size of boiler( mm) | 3400× 1700×2100 | 4300×1900×2300 |

3900×2100×2500 |

4700×2200×2600 |

5200×2300×2700 |

5660×2400×2 |

|||||

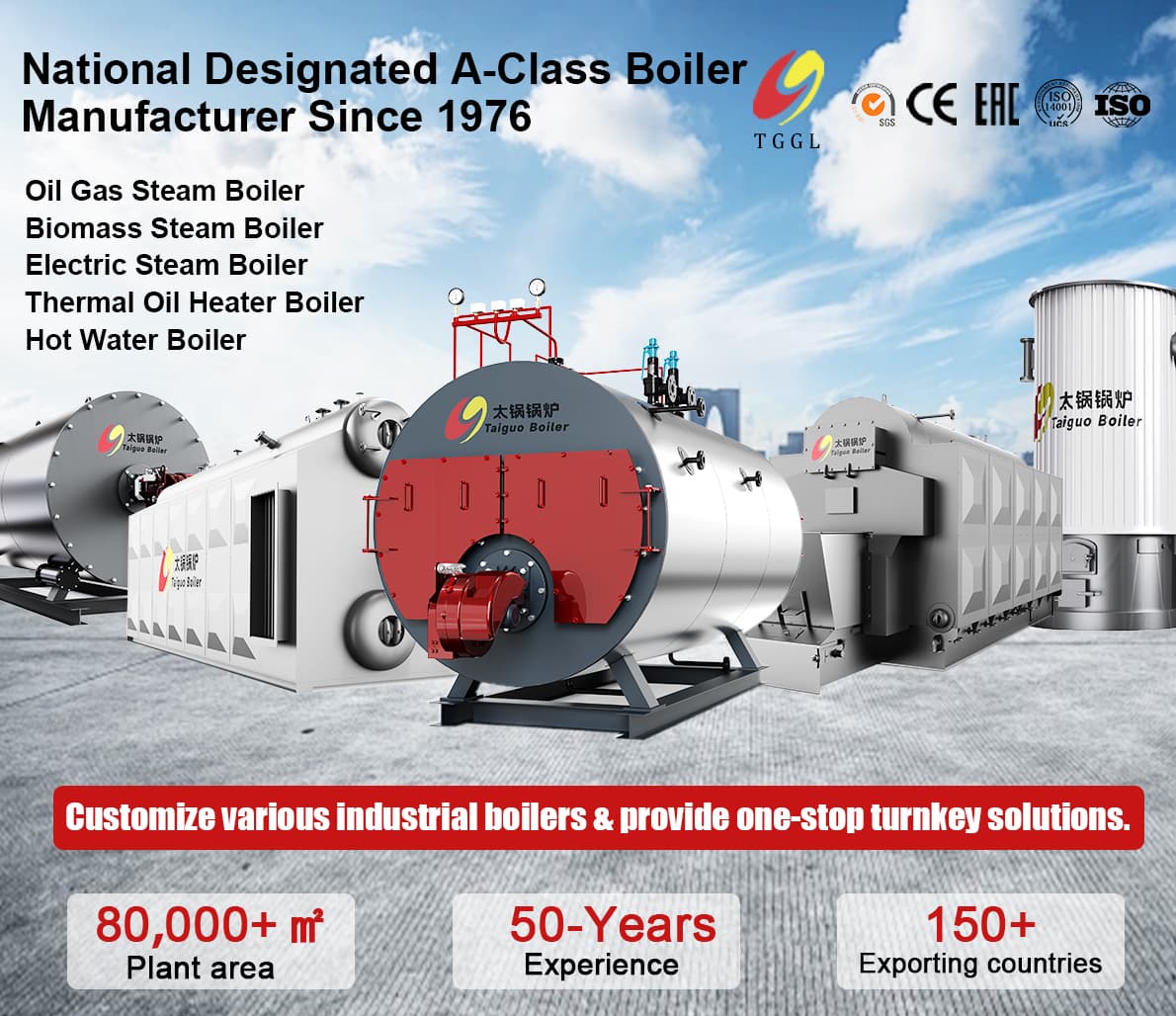

Why Choose Us?

Founded in 1976, Taiguo Boiler is National Designated A-Class Boiler Manufacturer to produce Class A boilers and D1/D2 pressure vessels, offering customized solutions from design to installation and commissioning, including boiler room planning.

Customer Visit

Welcome customers worldwide to visit our factory for inspections and technical exchanges. With extensive experience in receiving international clients, we ensure every visit is professional and rewarding.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.