The Impregnation Autoclave is a special timber protect machine designed for wood preservation, and it is made of high quality stainless steel with a production capacity of 10,000 sets per year. It has an 8000 cm tank length and a DN1000 tank diameter, and the storage medium is flammable and toxic. This Autoclave for Wood Preservation can ensure the timber is impregnated effectively and quickly, and it is a reliable and cost-effective solution for timber protection. The Impregnation Autoclave can provide excellent thermal insulation, stable working pressure and steady temperature control, which can effectively protect the timber from pests and decay. Moreover, it is equipped with an advanced control system to monitor the whole process of timber impregnation, guaranteeing the safety and reliability of the timber protection.

1.Tank door double safety interlocking protection device: The tank door adopts a double safety interlocking device to prevent unsafe accidents caused by workers accidentally opening the tank door when the equip-ment is under pressure

2.Advanced design of tank doors: The most advanced manual quick opening design concept in China allows formanual door opening and closing by a single person, making the operationfast, convenient, and safe. The tank door will not be unable to be opened dueto power outages

3.Good airtightness of the inflatable type: lt can be sealed by closing the door and inflating it. lt can release air andpressure to open the door, perfectly solving the problem oftank doorleakage. The sealing ring has a long service life.

4.High safety: Safety protection measures such as pressure automatic safety interlock,manual safety interlock, pressure automatic control, automatic safety valve,etc.

5.Simple and convenient operation: Adopting advanced and convenient design concepts and manufacturing processes, operators can learn all the operating procedures in just 10 minutes,with stable and reliable performance and good usage effects.

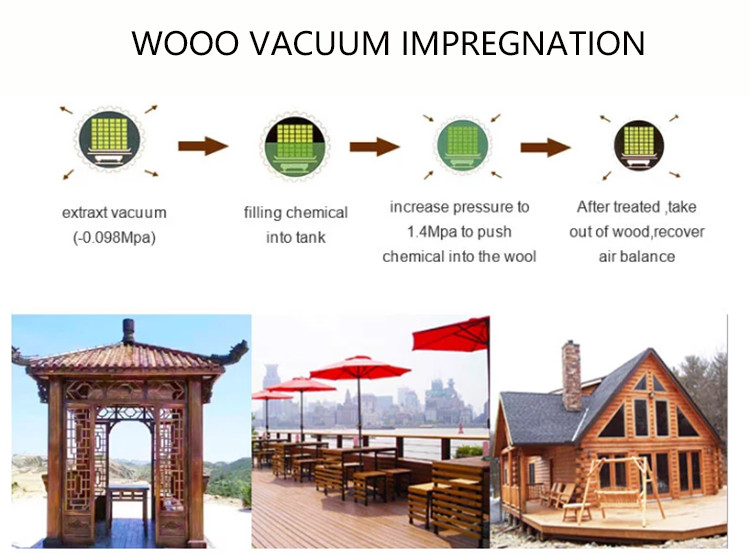

The timber impregnation process starts by forming a vacuum within the autoclave to remove air from the wood and generate pressure. The machine injects the untreated wood with a preservative. With the air removed, the preservative can thoroughly soak into the wood and will not harm its structure or appearance. The preservative improves the wood’s resistance to environmental wear, rain, and insect damage while also making the wood last longer. After processing, workers can remove the impregnated wood from the autoclave to dry and begin preparation for shipment.The anticorrosive wood, which has been treated by CCA,ACQ vacuum pressure, has been widely used in landscape engineering, architecture, outdoor furniture, garden facilities, such as: wooden house, chair wooden table, flower bed, fence, garbage can, pavilion, railing, wooden bridge engineering, wooden house, etc. Chairs, wooden tables, flower beds, fences, outdoor decoration, villa courtyard wooden rack, guardrail, square floor, tourist wharf, anticorrosive wood floor, flower rack, hydrophilic platform, fishing platform, wooden trestle, floor, ladder, handrail.

|

Tank diameter (cm) |

DN1000 |

DN1200 |

DN1500 |

DN2000 |

DN2200 |

DN2500 |

|

Tank length (cm) |

8000 |

8000 |

8000 |

8000 |

8000 |

8000 |

Wood processing capacity (m³) |

4 |

6 |

10 |

17 |

21 |

27 |

| Material: | Stainless Steel | Transport Package: | Full Container |

|---|---|---|---|

| Tank Length (cm): | 8000 | Tank Diameter (cm): | DN1000 |

| Control Mode: | Automatic | Safety Protection: | Pressure Relief Valve |

| Model: | Autoclave | Pressure Range: | Low Pressure (0.1MPa≤p<1.6MPa) |

| Application: | Mixture | Function: | Storage Pressure Vessel |

| Customization: | Available | Pressure Level: | Low Pressure (0.1MPa≤p<1.6MPa) |

| Highlight: |

Impregnation Autoclave DN1000,Wood Treatment Automatic Impregnation Autoclave,Wood Autoclave DN1000 |

||

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.